Scaffolding Supplier

Scaffolding materials are the components and equipment used in the construction of scaffolds, temporary structures that are erected to support workers and materials during construction, maintenance, or repair projects. Scaffolding materials can vary depending on the type of scaffold being constructed, the height and load capacity required, and the specific needs of the project.

Some common types of scaffolding materials include:

Scaffolding tubes: These are the main components used to create the scaffold structure. They are typically made of steel or aluminum and come in a range of lengths and diameters.

Couplers: These are used to connect the scaffold tubes together, providing stability and support to the overall structure.

Scaffold boards: These are the planks that are laid across the scaffold to provide a stable platform for workers and materials.

Base plates: These are placed at the bottom of the scaffold to provide a stable foundation and distribute the load evenly.

Adjustable jacks: These are used to level the scaffold on uneven ground and adjust the height of the scaffold.

Ladders: These are used to access the scaffold and to climb up and down the scaffold structure.

Safety equipment: This includes items such as guardrails, toe boards, and harnesses, which help to protect workers from falls or other potential hazards.

It's important to note that the specific scaffolding materials required for a particular construction project will depend on a variety of factors, including the type of scaffold being used, the height and load capacity required, and the nature of the work being performed. Proper selection and use of scaffolding materials is critical to ensuring the safety of workers and the stability of the scaffold structure.

Types of Scaffolding

Scaffolding is a temporary structure used to provide a platform for workers and materials during construction, maintenance, or repair work. The different most-used types of scaffolding in construction are given below:

Single Scaffolding:

Single scaffolding, also known as bricklayer's scaffolding, is a type of scaffolding used primarily for bricklaying work on a building's exterior walls. It is the simplest and most commonly used type of scaffolding, and consists of a single row of standards (upright tubes) placed parallel to the building, with ledgers (horizontal tubes) and transoms (small vertical tubes) to support the scaffolding boards or platforms.

The standards are usually made of steel or timber and are spaced at intervals of about 1.2 to 1.5 meters. The ledgers are placed horizontally on the standards, while the transoms are placed vertically to provide additional support. Scaffolding boards or platforms are then placed on top of the ledgers to create a working platform for the bricklayers.

Single scaffolding is quick and easy to assemble and dismantle, making it a popular choice for smaller projects. However, it is not suitable for very tall buildings or buildings with irregular shapes as it provides less stability than other types of scaffolding such as double scaffolding or cantilever scaffolding. Additionally, it may not be appropriate for use in high winds or other adverse weather conditions.

Double Scaffolding:

Double scaffolding refers to the use of two layers of scaffolding to support a wall or other vertical structure during construction or renovation. This technique is also known as "masonry scaffolding" or "brick scaffolding."

The first layer of scaffolding, called the "base" or "ground" layer, is constructed close to the wall and provides a stable foundation for the second layer. The second layer, called the "working" or "top" layer, is then constructed on top of the base layer and provides the workers with a stable platform from which to work.

The use of double scaffolding is common when building or renovating brick walls, as it provides a safe and stable platform for workers to stand on while they lay bricks or mortar. The technique can also be used to support other types of vertical structures, such as chimneys or towers.

Double scaffolding is typically constructed using metal pipes or tubes, which are connected together with couplers or clamps. The scaffolding is then secured to the wall using brackets or ties, which help to ensure that the scaffolding remains stable and secure during the construction process.

Suspended Scaffolding:

Suspended scaffolding, also known as swing stage scaffolding, is a type of platform used in construction and maintenance work that is suspended from the top of a building or structure by ropes or cables. This type of scaffolding is commonly used for high-rise buildings, bridges, and other structures where it is difficult to access the work area from the ground.

Suspended scaffolding typically consists of a platform that is supported by two or more ropes or cables, which are attached to the building or structure. The platform can be raised or lowered using a motor or manual mechanism, allowing workers to access different levels of the building or structure. The platform may also be equipped with guardrails and other safety features to protect workers from falls.

Suspended scaffolding is typically used for tasks such as painting, cleaning, and repair work on the exterior of buildings or structures. It is important to ensure that suspended scaffolding is installed and used correctly, as it can be dangerous if not properly secured and maintained. Workers who use suspended scaffolding should also receive appropriate training and follow safety protocols to minimize the risk of accidents and injuries.

Kwikstage Scaffolding:

Kwikstage scaffolding is a type of modular scaffolding system used in construction to provide temporary access and support to workers and materials at various heights. The system is made up of pre-fabricated steel components that can be easily assembled and dismantled, making it ideal for use in a wide range of construction projects.

Kwikstage scaffolding is designed to be highly flexible and adaptable, and can be used to create scaffolding structures in a variety of shapes and sizes, including straight runs, corners, and curves. The system is also highly versatile, and can be used for a wide range of applications, from basic access scaffolding to more complex temporary structures for supporting heavy loads.

Some of the key benefits of Kwikstage scaffolding include its speed and ease of assembly, its high strength-to-weight ratio, and its ability to be adapted to fit the specific needs of a given construction project. It is also highly durable and able to withstand harsh environmental conditions, making it suitable for use in a wide range of construction environments.

Cantilever Scaffolding:

Cantilever scaffolding is a type of scaffolding system used in construction that allows a platform to be extended beyond the edge of a building or structure. This type of scaffolding is commonly used when work needs to be done on the upper floors of a building that has no ground-level access, or when access to the ground is restricted.

The basic principle of cantilever scaffolding is that it uses horizontal beams, called needles, to extend the platform out from the building. The needles are supported by vertical tubes, called standards, which are attached to the building or other supporting structure. The platform is then supported by brackets, which are attached to the needles.

Cantilever scaffolding is a versatile and adaptable system that can be used in a variety of different applications, from simple maintenance tasks to more complex construction projects. It is commonly used in situations where there is limited access to the work area, or where the work area is located at a height that cannot be reached by conventional scaffolding systems.

Some of the key advantages of cantilever scaffolding include its ability to provide access to hard-to-reach areas, its high level of stability and safety, and its flexibility and adaptability to a wide range of construction environments. However, it is important to note that cantilever scaffolding can be more complex and time-consuming to set up than other scaffolding systems, and requires a high level of expertise and experience to use effectively.

Patented Scaffolding:

Patented scaffolding refers to a type of scaffolding system that is protected by a patent. This means that the design and construction of the scaffolding system are protected by intellectual property laws, and only the patent holder has the right to manufacture or sell the patented scaffolding.

In construction, scaffolding is used to provide a safe working platform for workers at heights. It is commonly used during building construction, maintenance, and repair works. Patented scaffolding systems offer several advantages over traditional scaffolding systems, including improved safety, easier assembly and disassembly, and increased versatility.

Patented scaffolding systems are typically made from lightweight, high-strength materials such as aluminum or steel. They can be designed to fit specific construction needs and can be easily adjusted to different heights and configurations. This makes them particularly useful in complex building projects where traditional scaffolding may not be practical.

When using patented scaffolding in construction, it is important to ensure that the system is properly installed and maintained according to the manufacturer's instructions. Workers using the scaffolding should also receive appropriate training and follow all safety guidelines to prevent accidents and injuries.

Overall, patented scaffolding is a valuable tool in the construction industry, offering enhanced safety and flexibility for workers at heights.

Trestle Scaffolding:

Trestle scaffolding is a type of scaffolding system commonly used in construction for a variety of purposes such as building, maintenance, and repair works. It consists of a series of vertical supports or posts, called trestles, which are connected by horizontal members, such as planks or boards, to create a stable platform for workers.

The trestles are usually made of timber or steel and are designed to be adjustable so that the platform can be set at different heights. The horizontal members are then laid across the trestles to create the working platform.

Trestle scaffolding is a relatively simple and cost-effective scaffolding system that can be easily erected and dismantled. It is particularly useful for small or short-term projects, or for situations where access is required to areas that are difficult to reach using other types of scaffolding.

However, trestle scaffolding has some limitations. It is not suitable for high-rise buildings or projects that require workers to access multiple levels, as it is not designed to provide the necessary stability at greater heights. Trestle scaffolding also has a limited weight capacity, which can restrict the amount of equipment and materials that can be used on the platform.

As with all scaffolding systems, it is important to ensure that trestle scaffolding is properly installed and maintained, and that workers receive appropriate training and follow all safety guidelines to prevent accidents and injuries.

Mobile Scaffolding:

Mobile scaffolding, also known as rolling scaffolding or tower scaffolding, is a type of scaffolding system that is designed to be easily moved around a construction site. It is typically made of lightweight materials such as aluminum or steel, and consists of a platform supported by wheels or casters, and a vertical frame that can be adjusted to different heights.

Mobile scaffolding is commonly used in construction for a variety of purposes, including painting, plastering, and electrical work. It is particularly useful in situations where access is required to different parts of a building or structure, and where a fixed scaffold may be impractical or inconvenient.

One of the main advantages of mobile scaffolding is its mobility. It can be easily moved from one location to another, either manually or by using a powered vehicle, allowing workers to access different areas of a building or structure without the need for dismantling and reassembling the scaffold.

Mobile scaffolding is also relatively easy to assemble and dismantle, which can save time and labor costs on construction projects. It can be set up quickly and easily by a small team of workers, and can be adjusted to different heights and configurations to suit the needs of the project.

However, it is important to ensure that mobile scaffolding is properly installed and maintained, and that workers receive appropriate training and follow all safety guidelines to prevent accidents and injuries. This includes ensuring that the scaffold is stable and secure, that it is not overloaded with equipment or materials, and that workers use appropriate fall protection equipment when working at heights.

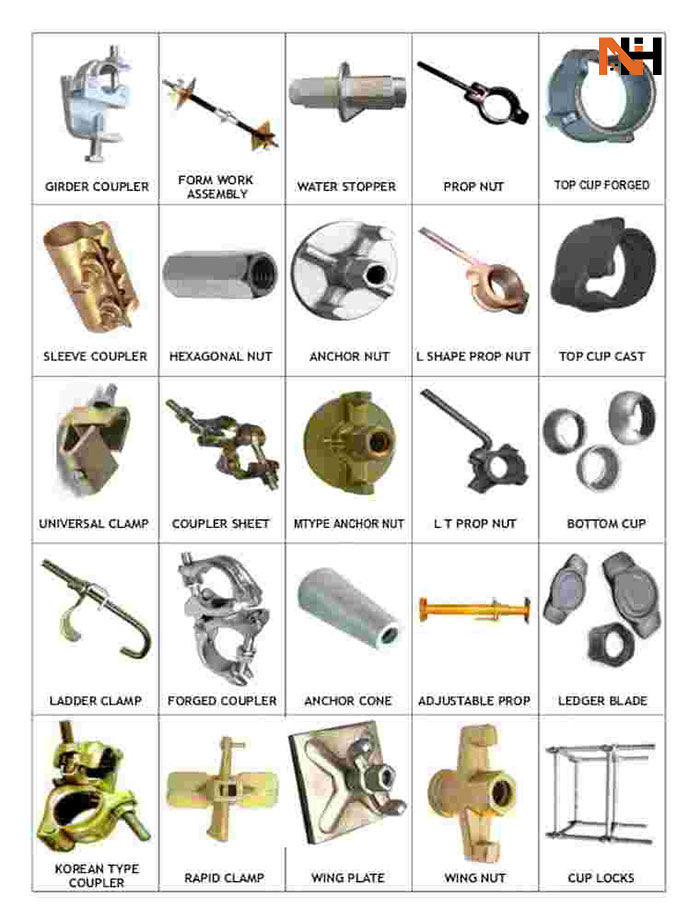

Scaffolding Components:

Scaffolding is a temporary structure used to support people and materials during construction, maintenance, or repair of a building or other structure. Scaffolding components are the individual parts that make up a scaffold system. Here are some common components of a scaffold:

Standards: Vertical

members that form the main support of the scaffold.

Ledgers: Horizontal

members that connect the standards together and provide support for the

platforms.

Transoms: Horizontal

members that provide additional support for the platforms.

Braces: Diagonal

members that provide lateral stability to the scaffold.

Base plates: Flat plates

that are used to distribute the weight of the scaffold and prevent it from

sinking into the ground.

Couplers: Connectors

that join scaffold tubes together and provide a secure and rigid connection.

Toe boards: Horizontal boards that are fixed to the scaffold to prevent people and materials from falling off.

Guardrails: Vertical

rails that are fixed to the scaffold to provide additional safety for workers.

Platforms: Boards

that are placed across the scaffold to provide a working surface for workers

and materials.

Ladders: Vertical

members that are used to access the scaffold and the working platform.

It is important to ensure that all scaffold components are of high quality and are assembled correctly to ensure the safety of workers and the stability of the structure.

Necessity of Scaffolding in Construction Site:

Scaffolding is an essential part of any construction project, providing a temporary structure that allows workers to safely access high areas of a building during construction, maintenance, or repair work. Here are some of the key reasons why scaffolding is important during construction:

1. Safety: Scaffolding provides a safe and stable platform for workers to perform their tasks at heights, reducing the risk of accidents, falls, and injuries. It also protects workers from falling debris, tools, and materials that could cause harm.

2. Access: Scaffolding provides workers with easy access to hard-to-reach areas of a building, such as roofs, ceilings, and upper floors. This makes it easier to perform tasks and carry out construction work efficiently.

3. Stability: Scaffolding is designed to be stable and secure, providing a reliable platform for workers to stand and work on. This makes it much safer than using ladders or other unstable platforms, which can increase the risk of falls and other accidents.

4. Productivity: Scaffolding can increase productivity on the construction site by providing workers with a stable and safe platform to work from. This can help to reduce the amount of time spent on a project and increase overall efficiency.

5. Compliance: Scaffolding is often required by law to ensure that workers are protected from falls and other hazards while working at heights. By providing scaffolding on a construction site, companies can comply with safety regulations and avoid penalties or legal liability.

In summary, scaffolding is an important component of any construction project, providing a safe and stable platform for workers to perform their tasks at heights. It can also increase productivity, ensure compliance with safety regulations, and reduce the risk of accidents and injuries.

Various Usage of Scaffolding:

Scaffolding is a temporary structure used to support workers and materials during construction, maintenance, or repair work. It typically consists of steel or aluminum tubes and boards that are assembled together to form a stable platform.

Some of the common uses of scaffolding include:

1. Construction: Scaffolding is essential for construction workers to reach and work on higher levels of buildings safely. It provides a sturdy and stable working platform, allowing workers to perform their tasks with ease.

2. Maintenance and repair work: Scaffolding is also used for maintenance and repair work on buildings, bridges, and other structures. It provides workers with access to hard-to-reach areas, making it easier for them to perform repairs or maintenance tasks.

3. Painting and cleaning: Scaffolding is often used for painting and cleaning the exteriors of tall buildings. It allows workers to access every part of the building's exterior, making it easier for them to paint or clean windows and other surfaces.

4. Event staging: Scaffolding can be used to create temporary stages for concerts, festivals, and other events. It can be customized to suit the needs of the event and provide a safe and stable platform for performers.

5. Demolition: Scaffolding can also be used for demolition work. It provides a safe and stable working platform for workers to dismantle buildings and structures, reducing the risk of accidents and injuries.

Overall, scaffolding is a versatile and essential tool for various industries and tasks that involve working at height.

Why Choose N. Hasnat Infrastructure as the Best Scaffolding Supplier:

Choosing N. Hasnat Infrastructure the best company for supplying scaffolding is important for several reasons:

Safety: Scaffolding

is an essential component of construction projects, and safety is a top

priority in construction. N. Hasnat Infrastructure the best scaffolding

companies has a reputation for providing high-quality and safe scaffolding

equipment. They ensure that their scaffolding is regularly inspected,

maintained, and installed by trained professionals to minimize the risk of

accidents.

Compliance: N.

Hasnat Infrastructure the best scaffolding companies comply with all relevant

regulations, standards, and codes of practice in the industry. They have a good

understanding of the safety and health regulations and take all necessary

precautions to protect the workers and the public.

Reliability: N.

Hasnat Infrastructure is one of the reliable scaffolding suppliers that

delivers high-quality scaffolding on time, every time. They have the capacity

to meet the needs of their clients and provide excellent customer service. This

helps to ensure that the project runs smoothly and on schedule.

Cost-effective: Choosing

N. Hasnat Infrastructure the best scaffolding company can help save costs in

the long run. Reliable and high-quality scaffolding minimizes the need for

frequent repairs, which can add up over time. Additionally, good scaffolding

companies offer competitive pricing and value for money.

Expertise: N.

Hasnat Infrastructure the best scaffolding companies have experienced

professionals who can provide expert advice on the most suitable scaffolding

for a particular project. They can offer customized solutions that meet the

specific requirements of each project. This can help to ensure that the project

is completed efficiently and safely.

Overall, choosing N. Hasnat

Infrastructure the best scaffolding company is important to ensure the safety,

compliance, reliability, cost-effectiveness, and expertise required for a

successful construction project.